I'm stripping! My gears!

From time to time you might come across a particular model that seems to be susceptible to stripping gears and in particular, the crown gear. There could be a number of factors causing this to happen and listed below are some possible causes and remedies.

- Too much lateral movement of the axle as the motor shaft is too narrow for the auto align feature on the crown gear; and/or

- The chassis is too weak for the amount of motor torque (when the motor applies torque to the rear axle the chassis may flex, causing rear axle movement).

There are a number of ways that this could be rectified and a few options are listed below:

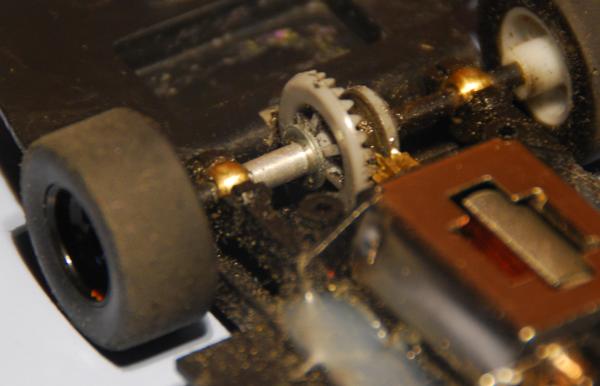

- Shimming could be applied on the side of the rear axle between the crown gear and the axle bearing

restricting the axle from moving side to side, thus promoting better meshing between the pinion and crown gear.

This could be a good option if you do not want to modify the chassis or buy aftermarket gears.

- Shimming between the axle bearings and the rims to restrict the axle from moving side to side may also be an option if the design of the running gear allow for it. In the example above which is an SCX NASCAR it did not allow for this option, which is why shimming was applied on the inside of the axle bearing.

- Stiffening the chassis, gluing in the motor to the chassis and gluing the axle bearings to the chassis could all also help improve proper meshing of both the crown and pinion gears.

- Replacing the crown gear with a good quality aftermarket

gear could also help. This could also include a crown gear

that is not pressed onto the axle but kept in place with a

grub screw which would allow for fine adjustment of the

position of the crown gear for better meshing.